When you take a pill, you expect it to be safe, effective, and exactly what the label says. That’s not luck—it’s the result of systems like Zone 1-4 sampling, a structured method used in pharmaceutical manufacturing to test drug batches for consistency, purity, and contamination. This process ensures that every tablet, capsule, or liquid in a shipment meets strict standards before it reaches your pharmacy. It’s not just about checking one sample—it’s about testing multiple zones across a production line to catch problems early.

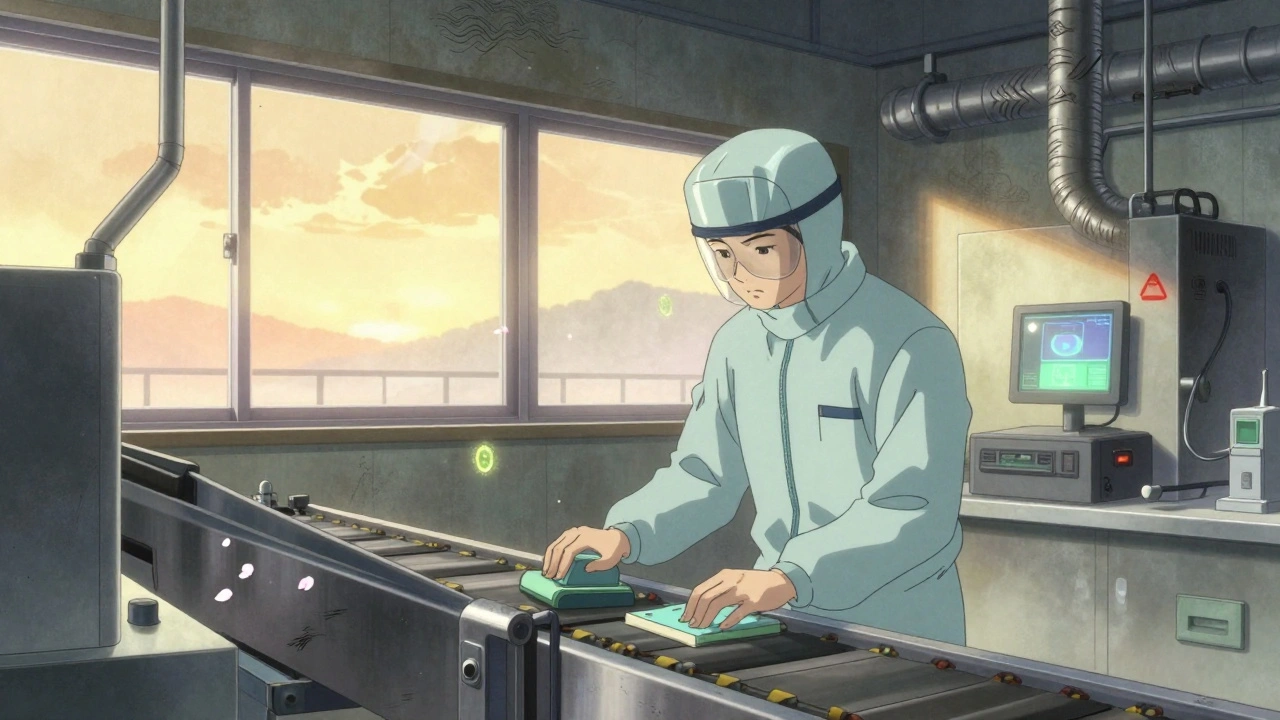

Zone 1-4 sampling isn’t a single test. It’s a strategy. Zone 1, typically the first point of material entry, is checked for raw ingredient quality. Zone 2, often the mixing or blending area, ensures ingredients are evenly distributed. Zone 3, the compression or filling stage, checks for weight, hardness, and uniformity. And Zone 4, the final packaging area, looks for labeling errors, contamination, or tampering. Together, these zones create a safety net that catches mistakes before they become dangerous.

This system matters because fake or faulty meds don’t always look different. A counterfeit pill might have the right color and shape but the wrong active ingredient—or none at all. That’s why regulators and manufacturers rely on sampling across zones to detect inconsistencies that visual checks miss. It’s the same logic behind why we test generics for bioequivalence, why we track pharmacy errors, and why we warn about counterfeit drugs sold online. Zone 1-4 sampling is the quiet backbone of every safe medication you take.

You won’t see it on your prescription, but if a drug batch fails Zone 3 testing, it never makes it to your shelf. If Zone 4 catches a mislabeled bottle, it gets destroyed. These steps are why buying generics abroad can be risky—if those samples weren’t tested under the same standards, you’re gambling with your health. And that’s why reports on counterfeit medication, medication errors, and real-world drug safety all tie back to the same foundation: proper sampling and quality control.

What you’ll find below isn’t just a list of articles. It’s a map of how drug safety actually works—from how generics are tested, to how side effects are tracked, to how you can spot a fake pill before you swallow it. Every post here connects to the same goal: making sure what you take does what it’s supposed to—and nothing more.

Environmental monitoring in manufacturing prevents contamination by testing air, surfaces, and water for microbes and chemicals. Learn how zone-based sampling, ATP testing, and regulatory standards keep products safe.

CONTINUE READING