When you take a manufacturing quality, the set of standards and processes that ensure a drug is made consistently, safely, and effectively. It’s not just about the active ingredient—it’s about how it’s mixed, pressed, coated, and tested before it lands in your pill bottle. A generic drug might have the same chemical as the brand name, but if the manufacturing quality is poor, you could get inconsistent doses, harmful fillers, or even fake pills. This isn’t theory—it’s why some people feel worse after switching to a generic, and why counterfeit drugs keep showing up online.

FDA standards, the strict rules enforced by the U.S. Food and Drug Administration to ensure drug safety and effectiveness require generics to meet the same bioequivalence benchmarks as brand-name drugs. But here’s the catch: the FDA inspects fewer than 10% of foreign manufacturing plants each year. Most generic drugs sold in the U.S. are made overseas—in India, China, and elsewhere—where oversight varies. That’s why counterfeit medication, fake drugs that look real but contain wrong ingredients, no active drug, or dangerous contaminants is such a growing threat. You can’t always tell by looking. A pill might have the right color and logo but contain nothing but flour, chalk, or worse—fentanyl.

Manufacturing quality affects everything: how fast a pill dissolves, whether it breaks down the same way in your body, and if it’s free from toxic byproducts. That’s why some patients report side effects after switching brands—not because the active drug changed, but because the inactive ingredients did. Cornstarch, dyes, or binders from a different factory can trigger reactions in sensitive people. And if the factory skips stability tests, your pills might lose potency before the expiration date.

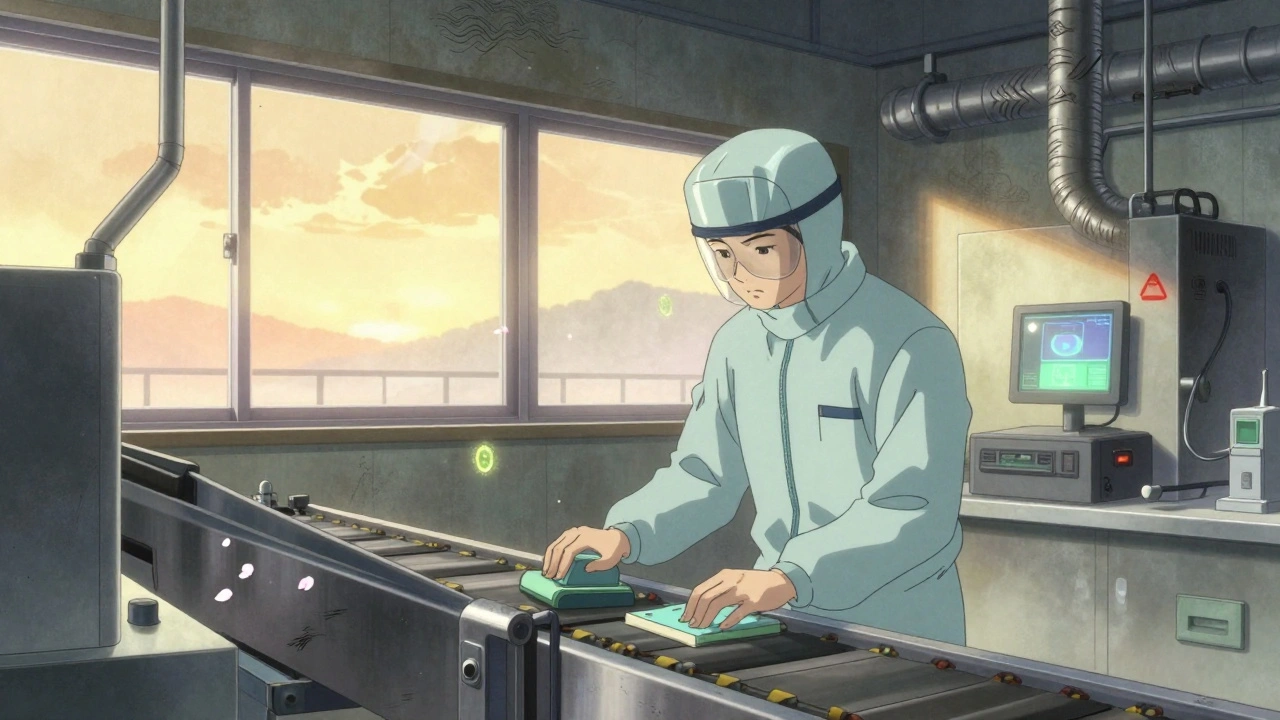

Drug safety doesn’t start at the pharmacy. It starts in a factory thousands of miles away, with workers, machines, and inspections you never see. That’s why knowing the difference between a well-made generic and a risky one matters. You’re not just choosing cost—you’re choosing trust. Below, you’ll find real stories and data about how manufacturing flaws lead to side effects, how to spot fake pills, why some generics work better than others, and what to do if you suspect your medicine isn’t what it claims to be.

Environmental monitoring in manufacturing prevents contamination by testing air, surfaces, and water for microbes and chemicals. Learn how zone-based sampling, ATP testing, and regulatory standards keep products safe.

CONTINUE READING