When your local pharmacy runs out of your regular blood pressure medication, or your doctor says the new insulin brand isn’t available for another six weeks, it’s not just bad luck. It’s the result of pricing pressure and shortages - two forces reshaping healthcare economics in real time. These aren’t abstract economic terms. They’re daily realities for patients, providers, and pharmacies across Australia and beyond.

Why Medicines Disappear From Shelves

In 2022, Australia’s Therapeutic Goods Administration recorded over 1,200 medicine shortages - a 35% increase from 2020. These weren’t random glitches. They were symptoms of deeper systemic strain. A single drug like metformin, used by millions for type 2 diabetes, vanished from shelves in multiple states. Why? Because its active ingredient is manufactured in just three countries - India, China, and Italy. When a factory in India shut down for safety inspections, and shipping delays hit Mediterranean ports, global supply collapsed. Demand didn’t drop. Prices didn’t rise fast enough. So shelves went empty. The same thing happened with antibiotics, asthma inhalers, and even basic IV fluids. The World Health Organization found that 50% of low- and middle-income countries faced critical shortages of essential medicines during 2021-2023. Australia, despite its strong system, wasn’t immune. The Australian Institute of Health and Welfare reported that 68% of hospitals experienced at least one drug shortage lasting more than 30 days in 2022.How Pricing Pressure Turns Scarcity Into Crisis

When supply drops but demand stays high - especially for life-saving drugs - prices don’t always jump immediately. That’s because many medicines are price-regulated. In Australia, the Pharmaceutical Benefits Scheme (PBS) sets what pharmacies can charge. But when manufacturers can’t produce enough, they don’t always raise prices. Instead, they cut supply to the most profitable markets. The result? A double hit. Patients in countries with strict price controls - like Australia, Canada, and the UK - face shortages. Meanwhile, those in unregulated markets, like the U.S., pay 3-5 times more for the same drug. A 2023 study in The Lancet showed that generic insulin prices in the U.S. were 400% higher than in Australia, even though both countries sourced from the same manufacturers. The problem? When prices can’t rise to match scarcity, production shifts away. It’s not greed. It’s economics.The Domino Effect on Care

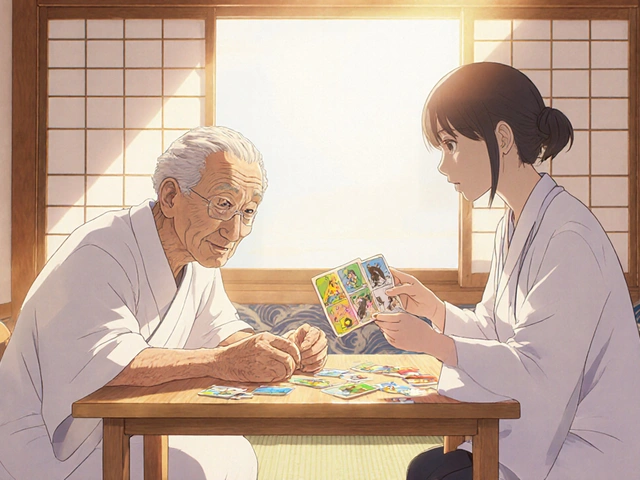

Shortages don’t just mean empty shelves. They mean delayed treatments, risky substitutions, and more hospital visits. In 2022, a shortage of the chemotherapy drug doxorubicin forced oncologists in Adelaide to delay treatments for 18% of new breast cancer patients. Some switched to older, less effective alternatives. Others waited - sometimes for months. Even routine care suffered. A 2023 survey of 200 Australian general practices found that 71% had to postpone non-urgent procedures because they couldn’t get basic supplies like syringes, IV tubing, or even sterile gloves. One clinic in Port Adelaide switched to reusing single-use syringes - a practice banned under health regulations - just to keep up. The ripple effects hit harder for vulnerable groups. Elderly patients on fixed incomes couldn’t afford higher-priced alternatives. Rural patients had no backup pharmacies. Indigenous communities, already facing healthcare gaps, saw their medication access shrink further.

Who’s Behind the Bottlenecks?

It’s easy to blame global supply chains - and they’re a big part of it. But the real issue is fragility. Over the last 20 years, drug manufacturing has become hyper-concentrated. In 2021, 85% of active pharmaceutical ingredients (APIs) used in Australia came from just two countries: China and India. That’s a 40% increase since 2010. When a single factory in Mumbai shuts down - whether due to flooding, power cuts, or regulatory crackdowns - it doesn’t just affect one drug. It affects dozens. Because APIs are used as building blocks for multiple medicines. One API shortage can trigger a chain reaction across 10-15 different prescriptions. Labor shortages make it worse. Australia’s pharmaceutical manufacturing sector has lost 17% of its skilled workers since 2020. Fewer people to monitor quality, run machines, or ship goods. And when you can’t hire enough technicians to fill vials or package pills, production slows - even if raw materials are available.Why Price Controls Can Make Things Worse

Many assume government price controls protect patients. In theory, yes. In practice? They often delay the market’s natural response. When a drug’s price is capped and supply drops, manufacturers don’t get paid more to make more. So they make less. Or they stop making it altogether. In 2021, the UK’s National Health Service saw 47 generic drugs vanish from its formulary after manufacturers cited “unsustainable margins.” Australia avoided mass withdrawals - but only because PBS prices were kept artificially low. That meant fewer companies wanted to produce these drugs here. The result? A slower, quieter shortage - but one that lasted longer. A 2023 study by the Grattan Institute found that medicines with price controls were 3 times more likely to experience prolonged shortages than those sold in unregulated markets. The study concluded: “Price caps may reduce short-term costs, but they increase long-term risk.”

What’s Being Done - And What’s Not

Some steps are being taken. In 2023, the Australian government launched the National Medicine Supply Strategy. It includes:- Stockpiling 6 months’ supply of 30 critical medicines

- Offering tax breaks to local manufacturers

- Fast-tracking approvals for alternative suppliers

What Comes Next?

The solution isn’t just more money or better regulations. It’s resilience. - Diversify sourcing: Relying on two countries for 85% of your APIs is a gamble. Australia needs to build partnerships with more stable suppliers - in Southeast Asia, Eastern Europe, or even South America. - Incentivize local production: Tax credits alone won’t cut it. We need grants for building new API plants, training technicians, and certifying quality labs. Germany’s model - where the government co-invests 50% in domestic drug manufacturing - cut its shortages by 60% in five years. - Allow flexible pricing: For critical, low-margin drugs, let prices rise modestly when shortages occur. Not to gouge - but to signal demand and trigger production. The U.S. FDA now allows temporary price adjustments for drugs in shortage. Australia should consider the same. - Use tech to predict shortages: Hospitals in Melbourne and Sydney are testing AI tools that track global shipping delays, factory outages, and raw material prices. One system predicted a 3-month shortage of epinephrine 11 weeks before it happened - giving time to reroute supplies.What You Can Do

As a patient, you can’t fix global supply chains. But you can reduce your own risk:- Ask your pharmacist if your prescription has a substitute - and if it’s safe

- Don’t stockpile. It makes shortages worse for others

- Sign up for alerts from the TGA or your local health service

- Support policies that fund local medicine production

Why do drug shortages happen even when there’s plenty of raw material?

Raw materials are only one part of the chain. Even if you have the chemicals, you need factories to turn them into pills, workers to operate the machines, packaging materials, and transport to deliver them. When any one of these steps breaks - due to labor shortages, shipping delays, or regulatory shutdowns - production stops. A 2023 study found that 62% of medicine shortages were caused by issues in manufacturing or packaging, not raw material scarcity.

Are generic drugs more likely to be in short supply than brand-name drugs?

Yes. Generic drugs often have thinner profit margins, so manufacturers are less willing to invest in backup production lines or maintain spare capacity. In 2022, 83% of all medicine shortages in Australia were for generic drugs. Brand-name drugs, with higher prices and more stable demand, are usually prioritized by manufacturers and distributors.

Can Australia produce its own medicines to avoid shortages?

It can - but it doesn’t yet. Australia currently produces only about 7% of the medicines it uses. Building local manufacturing capacity takes years and billions in investment. Some progress is being made: new facilities are opening in South Australia and Victoria to produce vaccines and injectables. But for everyday pills like antibiotics or blood pressure meds, we still rely almost entirely on imports.

Do price controls help prevent medicine shortages?

Not usually. Price controls keep costs low for consumers, but they also remove the financial incentive for manufacturers to ramp up production during shortages. When a drug’s price is capped and demand spikes, companies often cut supply instead of increasing output. This is why countries with strict price controls, like Australia and the UK, often experience longer and more frequent shortages than countries with flexible pricing.

What’s the difference between a temporary shortage and a permanent one?

A temporary shortage usually lasts under 90 days and is caused by a one-time event - like a factory fire or shipping delay. A permanent shortage happens when a drug is no longer profitable to make. If a generic drug’s price is too low to cover rising production costs, manufacturers quit making it entirely. Once that happens, it can take years for another company to step in - if they ever do.

Daz Leonheart

3 Feb, 2026

I've been on metformin for 8 years. When my pharmacy ran out last year, I had to drive 45 minutes to the next town. No one talked about it. Just silent suffering. This isn't a policy issue - it's a human one. We treat medicine like a commodity, but it's life or death.

Kunal Kaushik

4 Feb, 2026

In India, we make half the world's generic drugs. But our factories are old, power cuts are common, and workers get paid peanuts. No one talks about how the people making your medicine are barely surviving. We're not villains - we're the broken link in a chain someone else built.

Caleb Sutton

5 Feb, 2026

This is all a government plot. The pharmaceutical-industrial complex is deliberately creating shortages so they can push you into private insurance or worse - biometric tracking. They want you dependent. Watch the news. They're already testing AI in hospitals to ration care. This isn't economics. It's control.

Janice Williams

5 Feb, 2026

I find it profoundly irresponsible to suggest that price controls are the primary driver of pharmaceutical shortages. Such a conclusion ignores the structural inefficiencies inherent in global supply chains, the lack of investment in domestic manufacturing infrastructure, and the systemic underfunding of public health logistics. One cannot reduce complex policy outcomes to simplistic economic axioms.

Roshan Gudhe

7 Feb, 2026

It's funny how we all blame China or India, but we never ask why we outsourced so much in the first place. Profit over people. That’s the real story. I’ve seen this in my own village - a local clinic stopped stocking antibiotics because the government price was too low. The pharma company didn’t go broke - they just moved to a market where they could charge more. We’re not victims of supply chains. We’re victims of greed disguised as efficiency.

Rachel Kipps

7 Feb, 2026

I didn't realize that 83% of shortages were for generics. That's heartbreaking. My mom takes three generics - one for blood pressure, one for cholesterol, one for thyroid. She's on a fixed income. I'm going to call her pharmacist tomorrow and ask if they have alternatives. I never thought about how much this costs people emotionally.

Prajwal Manjunath Shanthappa

9 Feb, 2026

Let me be perfectly clear: the notion that Australia’s PBS model is 'effective' is a delusion perpetuated by ideologues who confuse austerity with equity. The fact that 30 critical medicines remain unsecured under the National Medicine Supply Strategy - a policy so tepid it’s practically a footnote - demonstrates not just incompetence, but moral bankruptcy. We are not managing healthcare. We are managing decline.

Wendy Lamb

9 Feb, 2026

I think we need to stop thinking of medicine as something that should be cheap. It’s not. It’s complex. It’s dangerous. It’s science. If we want reliable access, we need to pay for it - properly. That means funding local labs, paying workers a living wage, and accepting that some drugs will cost more. No one’s saying gouge. Just… don’t pretend we can have it all for $5.

Antwonette Robinson

10 Feb, 2026

Oh wow, so the solution is to let prices rise? Genius. Next you’ll say we should sell oxygen by the breath. What a brilliant plan - make sick people pay more for their survival. I’m sure the CEOs of Big Pharma are just waiting for someone to give them permission to be evil.

Ed Mackey

11 Feb, 2026

I work in a rural clinic. We had to reuse syringes last winter. Not because we wanted to. Because we had no choice. I’ve never felt so helpless. We’re not criminals. We’re just trying to keep people alive. The system failed us. And now we’re the ones getting blamed.

Alex LaVey

12 Feb, 2026

I’m from the U.S. and I’ve seen both sides. Here, insulin costs $300. In Australia, it’s $30. But here, you can get it tomorrow. There, you wait six weeks. There’s no perfect answer. Maybe the real question isn’t about price or supply - it’s about justice. Should a person’s access to life-saving medicine depend on which country they were born in? If the answer is yes… then we’ve already lost.